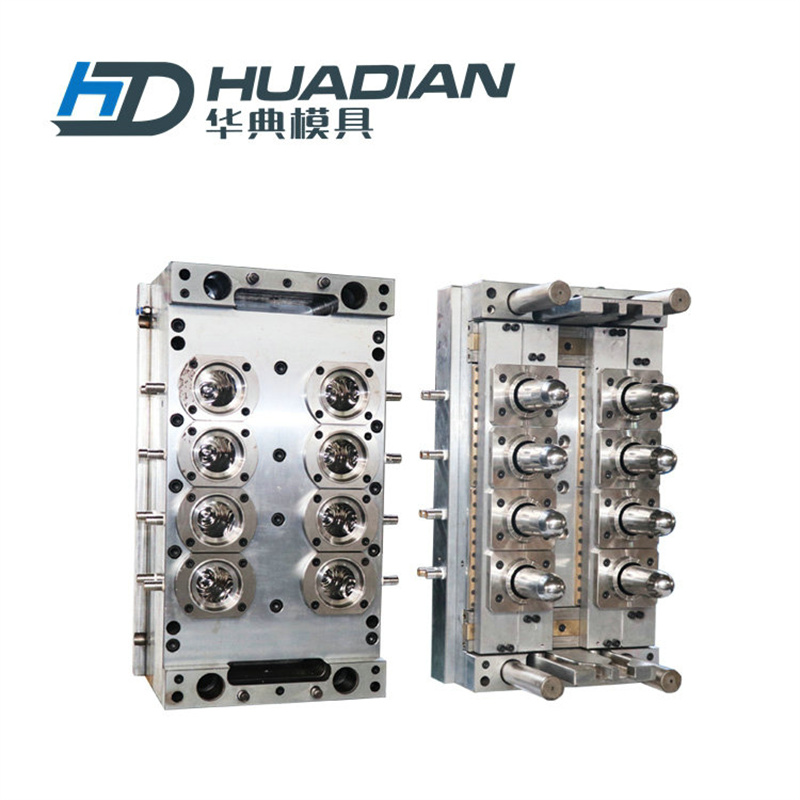

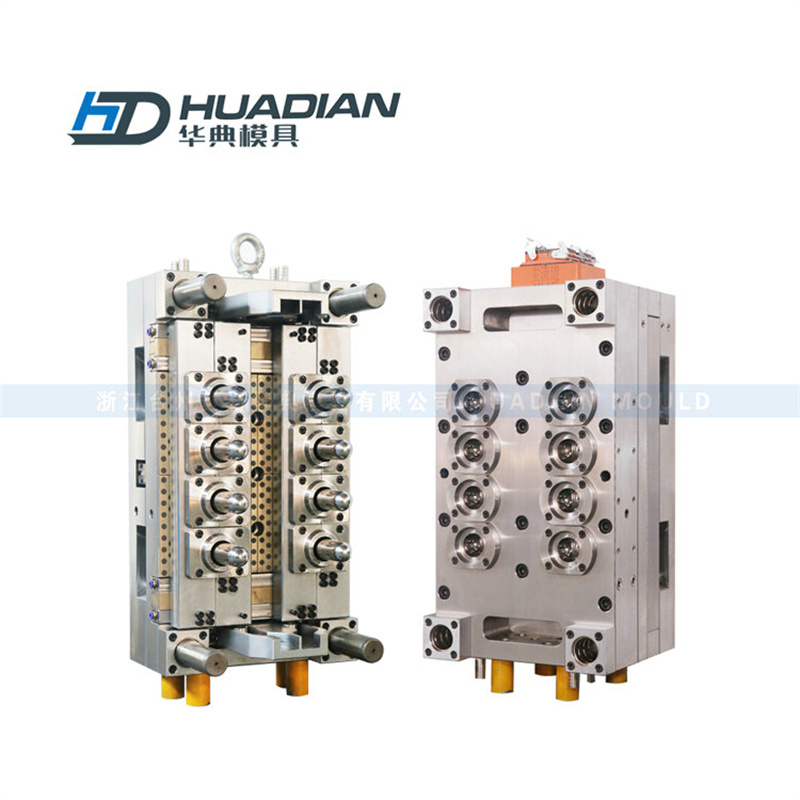

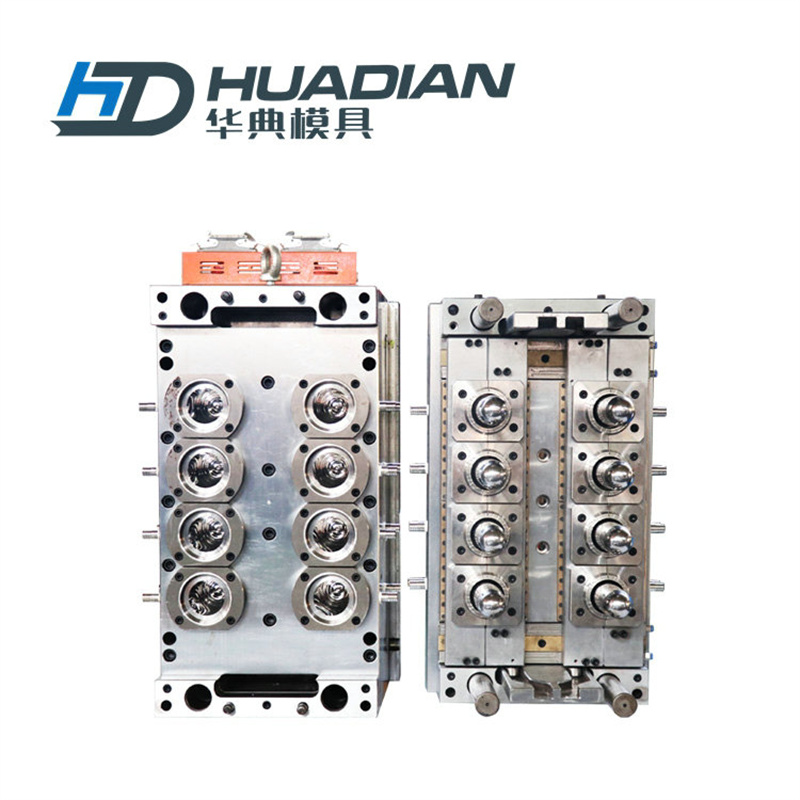

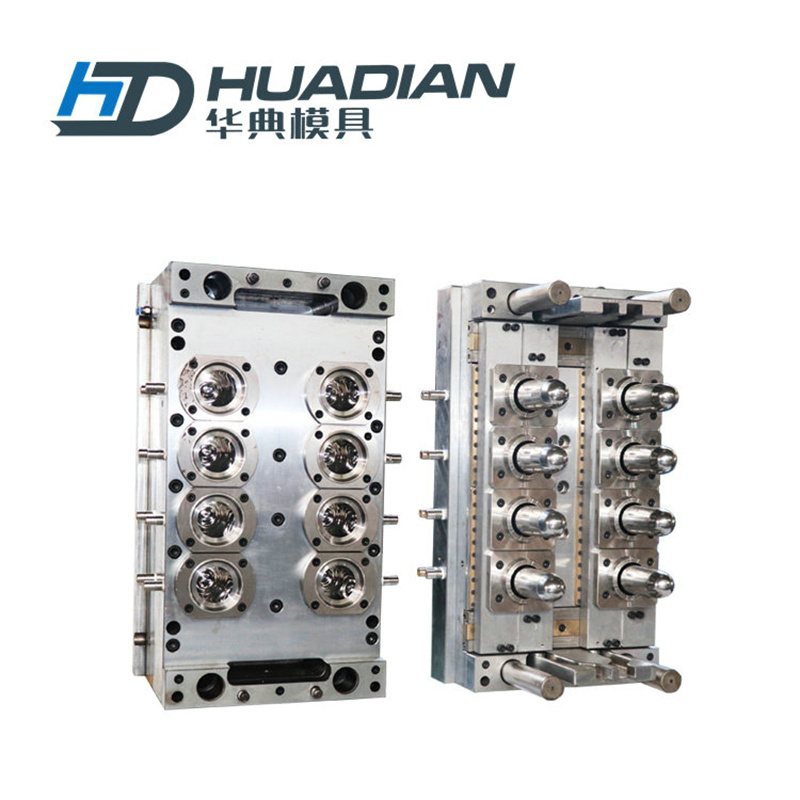

8 Cavities Oil bottle Hot Runner Perform Mold

Specifications

| 0il Bottle Size | 1L-2.5L | ||||||

| 1.8L- 2.5L | |||||||

| 10L | |||||||

| 20L | |||||||

| Neck | 32MM, 37MM, 46M, 46MM | ||||||

| 62MM, 72MK | |||||||

| 0il Bottle Eight | 20G, 25G, 28G, 30G, 35G, 40G, 40G, 43G | ||||||

| 50G, 55C, 600, 63G, 65C. 680, 700, 756, 77G, 82G | |||||||

| 85G, 90G, 93G, 95G, 100G, 120G, 140G, 145G, 150G | |||||||

| 175C, 230C, 245G, 250G | |||||||

The advantage on Hot Runner Technique

1. Reduce the wastage and cost of raw materials.

2. Reduce the work for recycle,classification,smash,dry,and store of waste, improve the work efficiency, save time and space.

3.Avoid to use the returned materials which will influence the quality of product.

4.Guarantee the product in the same quality level

5.Increase the injection volum,Improve the compressibiity of plastic melt

6.Intesify the injection function, improve the technique

7.Reduce the time of injection and pressure maintaining

8.Reduce Clamping force

9.Shorten Mold opening stroke of injection operation, Elimiate the time of taking out the Nozzle material

10.Shorten the injection cycle, improve the automation and work efficiency

Key Performance of Hot Runner System

1.Control the temperature of plastic melt precisely, Elimiate the degration of materials.

2.Naturally balanced runner desgin, Mold Cavity evenly filled.

3.Suitable size of Hot Nozzle can be sure the plastic melt mobile successfully and mold cavity are filled evenly.

4.Correct gate structure and size can guarantee the mold cavity evenly filled,Needle valve gate closed in time, to shorten cycle time.

5. No dead angle in runner, insure to change the color quickly, avoid materials degration.

6. Mininize Pressure lose

7. Pressure maintaining time is reasonable.

mold data

| Name | Pet Oil Bottl Perform Mold |

| Cavity And Core | S136(8, 12, 24, 48, 96HRC) |

| Mold Shelf | P20 |

| Cavity Qty | As Customi Zed |

| product Standard | Lkm, Dme, Hasco |

| Rotary Wheel Type | Hot Board |

| Cycle Time | Short |

| Software | UG, PROE, CAD |

| Perform Material | Pet |

| Perform SiZe | As Customi Zed |

| Working Life | 3-4Million |

| Delivery Time | 45-50DaysAYS |

If you're in the business of manufacturing oil bottles, then you know how important it is to have a reliable and efficient mold. The 8 Cavities Oil Bottle Hot Runner Perform Mold is a top-of-the-line mold that can help streamline your production process and improve your bottom line. In this article, we'll take a closer look at the features and benefits of this mold.

Features

The 8 Cavities Oil Bottle Hot Runner Perform Mold is a state-of-the-art mold that has been designed with precision and attention to detail. Here are some of its key features:

High-quality materials: The mold is made of high-quality materials that ensure its durability and stability during long-term use. It can withstand high temperatures and pressure, which makes it a great option for factories with high-volume production needs.

Hot runner technology: This mold features hot runner technology, which allows for more precise control over the injection molding process. It helps to prevent plastic waste and reduce production costs, making it a cost-effective option for factories.

8 cavities: With 8 cavities, this mold can produce eight oil bottles simultaneously, which greatly improves production efficiency. This feature is particularly useful for factories with high-volume production needs.

Compact size: The mold has a compact size, which makes it easy to store and transport. Its small footprint also means that it can be installed in smaller spaces, which is great for factories with limited space.

Benefits

The 8 Cavities Oil Bottle Hot Runner Perform Mold offers several benefits that can help improve your production process and bottom line. Here are some of the key benefits:

Improved production efficiency: With 8 cavities, this mold can produce eight oil bottles simultaneously, which greatly improves production efficiency. This means that factories can produce more oil bottles in less time, which can help increase their revenue and profitability.

Reduced plastic waste: The mold features hot runner technology, which allows for more precise control over the injection molding process. This helps to prevent plastic waste and reduces production costs, which can help improve your bottom line.

Cost-effective: The 8 Cavities Oil Bottle Hot Runner Perform Mold is a cost-effective option for factories. Its hot runner technology helps to reduce production costs, and its high-quality materials ensure its durability and stability during long-term use. This means that factories can save money on production costs and reduce their overall expenses.

Easy installation: The mold has a compact size, which makes it easy to install in smaller spaces. Its simple installation process also means that factories can save time and money on installation costs.

Applications

The 8 Cavities Oil Bottle Hot Runner Perform Mold is a versatile mold that can be used in a variety of applications. Here are some of the applications for this mold:

Oil bottle production: This mold is specifically designed for the production of oil bottles. With its 8 cavities and hot runner technology, it is a great option for factories looking to increase their oil bottle production capabilities.

Other bottle production: While this mold is designed for oil bottle production, it can also be used to produce other types of bottles.